Bulbs

Flower Basics

Flower Beds & Specialty Gardens

Flower Garden

Garden Furniture

Garden Gnomes

Garden Seeds

Garden Sheds

Garden Statues

Garden Tools & Supplies

Gardening Basics

Green & Organic

Groundcovers & Vines

Growing Annuals

Growing Basil

Growing Beans

Growing Berries

Growing Blueberries

Growing Cactus

Growing Corn

Growing Cotton

Growing Edibles

Growing Flowers

Growing Garlic

Growing Grapes

Growing Grass

Growing Herbs

Growing Jasmine

Growing Mint

Growing Mushrooms

Orchids

Growing Peanuts

Growing Perennials

Growing Plants

Growing Rosemary

Growing Roses

Growing Strawberries

Growing Sunflowers

Growing Thyme

Growing Tomatoes

Growing Tulips

Growing Vegetables

Herb Basics

Herb Garden

Indoor Growing

Landscaping Basics

Landscaping Patios

Landscaping Plants

Landscaping Shrubs

Landscaping Trees

Landscaping Walks & Pathways

Lawn Basics

Lawn Maintenance

Lawn Mowers

Lawn Ornaments

Lawn Planting

Lawn Tools

Outdoor Growing

Overall Landscape Planning

Pests, Weeds & Problems

Plant Basics

Rock Garden

Rose Garden

Shrubs

Soil

Specialty Gardens

Trees

Vegetable Garden

Yard Maintenance

How to Splice Low Voltage Landscape Lighting Wire

How to Splice Low Voltage Landscape Lighting Wire. Low-voltage landscape lighting systems are a great way to add accent lighting to your yard or garden. Systems will typically come with pre-cut lengths of wire, which can limit your placement of accent lights. To extend the low-voltage landscape lighting wires, you can splice in additional sections...

Low-voltage landscape lighting systems are a great way to add accent lighting to your yard or garden. Systems will typically come with pre-cut lengths of wire, which can limit your placement of accent lights. To extend the low-voltage landscape lighting wires, you can splice in additional sections of wire.

Things You'll Need

Low voltage lighting system

Wire cutters/strippers

Two-lead electrical wire

Heat-shrink tubing

Soldering iron

Rosin-core solder

Blow drier

Stretch out the existing low voltage landscape lighting wire (make sure it's disconnected from any power source first). Cut the wire in the middle with a pair of wire cutters.

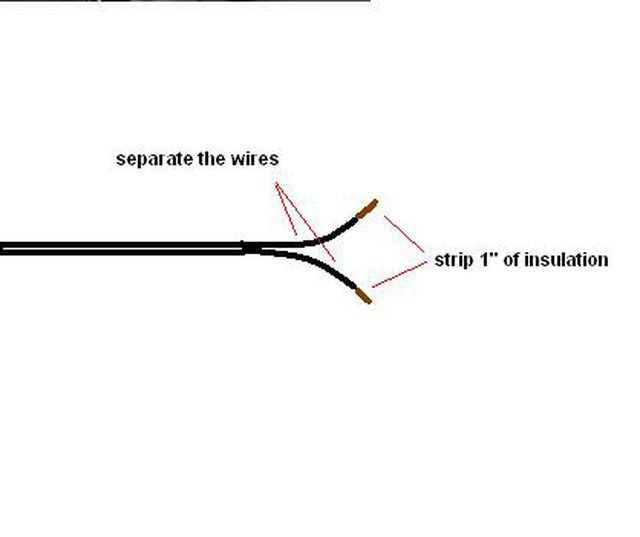

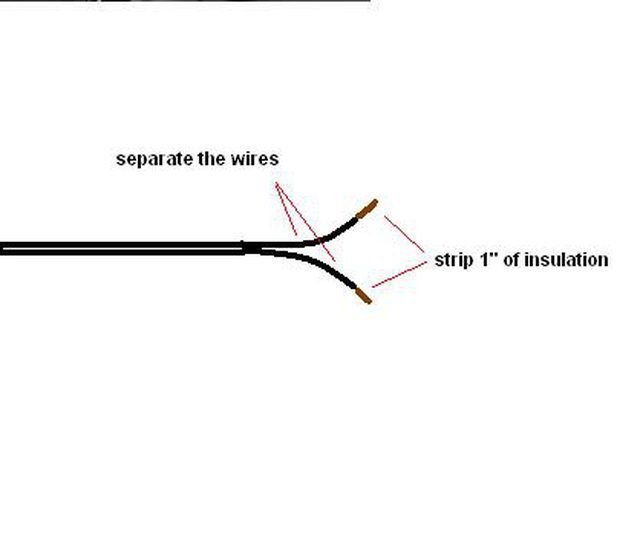

Strip the insulation from each of the cut ends of the wire, so that each wire's leads have about 1 inch of bare wire exposed. Pull apart the leads of each wire so that they are separated from each other for about 4-6 inches.

Take the wire you'll be inserting into the circuit. It should be of a similar gauge and construction. Cut a length that's long enough so that when inserted between the cut sections of the original wire you'll have enough wire to place your light in its destination. As in Step 2, separate the leads of the wire on the ends and strip about 1 inch of insulation from the leads.

On each of the leads of the new piece of wire, slide on a 2 inch long piece of heat-shrink tubing. There will be four pieces in total--two on each end of the new piece of wire.

Twist together the old and new wires to create a continuous length of two-lead wire. At each joint, apply a hot soldering iron, heat the wire, and then apply solder until it flows into the joint. Remove the soldering iron and repeat.

When the joints are cool, slide the pieces of heat-shrink tubing over the joints and direct the heat of a blow drier onto the tubing until it shrinks tight over the joints.

Plug your low-voltage system in and test operation, then place the wire and lighting fixtures as required.

Tips & Warnings

Heat shrink tubing will protect the splices you've made much more effectively than electrical tape, especially in the outdoors.

Even though this is a low-voltage application, don't work on live electrical circuits.