Bulbs

Flower Basics

Flower Beds & Specialty Gardens

Flower Garden

Garden Furniture

Garden Gnomes

Garden Seeds

Garden Sheds

Garden Statues

Garden Tools & Supplies

Gardening Basics

Green & Organic

Groundcovers & Vines

Growing Annuals

Growing Basil

Growing Beans

Growing Berries

Growing Blueberries

Growing Cactus

Growing Corn

Growing Cotton

Growing Edibles

Growing Flowers

Growing Garlic

Growing Grapes

Growing Grass

Growing Herbs

Growing Jasmine

Growing Mint

Growing Mushrooms

Orchids

Growing Peanuts

Growing Perennials

Growing Plants

Growing Rosemary

Growing Roses

Growing Strawberries

Growing Sunflowers

Growing Thyme

Growing Tomatoes

Growing Tulips

Growing Vegetables

Herb Basics

Herb Garden

Indoor Growing

Landscaping Basics

Landscaping Patios

Landscaping Plants

Landscaping Shrubs

Landscaping Trees

Landscaping Walks & Pathways

Lawn Basics

Lawn Maintenance

Lawn Mowers

Lawn Ornaments

Lawn Planting

Lawn Tools

Outdoor Growing

Overall Landscape Planning

Pests, Weeds & Problems

Plant Basics

Rock Garden

Rose Garden

Shrubs

Soil

Specialty Gardens

Trees

Vegetable Garden

Yard Maintenance

How to Add Water Weight to Tractor Tires

How to Add Water Weight to Tractor Tires. Tractors are an absolute necessity to farmers, contractors, loggers, highway departments, land owners and gentlemen farmers. To maximize their potential it is often advisable to maximize traction and stability. One of the best ways to do this is to add weight to the rear tires. By adding a mixture of...

Tractors are an absolute necessity to farmers, contractors, loggers, highway departments, land owners and gentlemen farmers. To maximize their potential it is often advisable to maximize traction and stability. One of the best ways to do this is to add weight to the rear tires. By adding a mixture of anti-freeze and water to each of the rear tires you increase the weight and stability of the machine. Using a non-toxic/non-corrosive anti-freeze and water mix will insure that you are not damaging either the tractor wheels or the environment. This article outlines a method of placing this mixture into the tires. Usually only the rear tires are filled with the mixture since the much smaller size of the front tires add no real advantage in gain of additional traction or stability.

Things You'll Need

Quantity of a non-toxic/non-corrosive anti-freeze (ref links for chart)

Portable air tank w/air hose

Air compressor/air hose

Tire air gauge

Water hose/water supply

Special valve stem fitting (available at automotive or farm supply stores)

Small hydraulic jack

Adjustable wrench and pliers

Plastic funnel medium to large size

Safety glasses or goggles

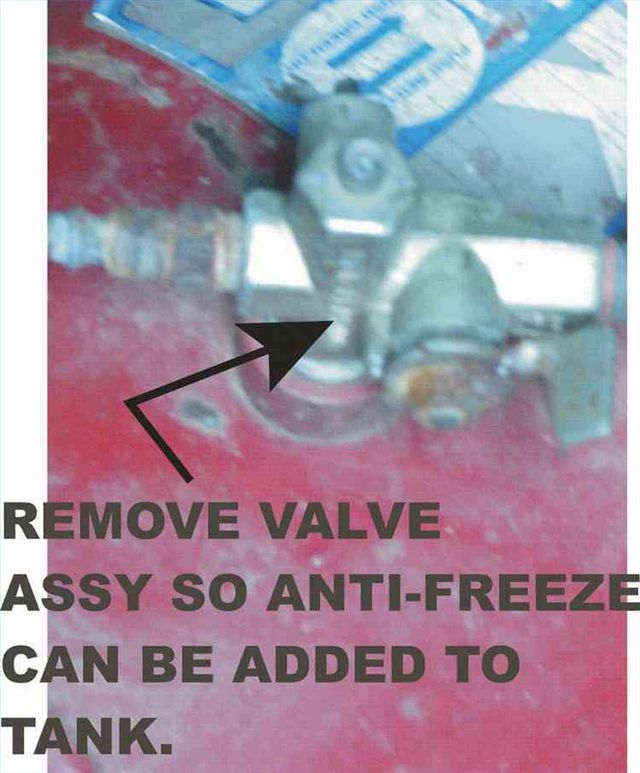

Jack up one of the tractor rear tires. If you happen to have a detachable back hoe for the tractor then so much the better since the hydraulic stabilizers can be used to lift the tires above grade. Remove the valve core from the valve stem so that all of the air exhausts. You can also do this by just depressing the valve stem core but it might take awhile because of the large volume of air involved. Some tractors have the rear tire mounted so that the valve stem is on the inside of the tire rim. This is a little harder to access but the steps are the same. After the air is all out replace the valve core. Now rotate the tire so that the valve stem is at the bottom (6 o'clock) position.

Be certain that the portable air tank is empty of air and pressure free. The air gauge which is a normal part of these type tanks should register zero. Remove the screwed fitting that where the on-off valve and air gauge connect to the tank. Place the funnel into the female opening in the tank and pour in the anti-freeze. The amount to be used is based on the volume of your tire (refer to links at the end of this article). It is better to use a greater amount of anti-freeze to be on the safe side. Solid freezing would not be very likely even in the event of extreme temperature drops and probably only a slush would form. Reinstall the valve mechanism on the air tank so that it is tight and leak free.

Using an air compressor, air up the portable air tank to a pressure somewhere below its pressure capacity - say 80 psi. Now begin to transfer the liquid from the tank into the tractor tire just as if you were airing it up with the hose from the tank. You might have to add additional air to the tank before all of the anti-freeze gets "blown" into the tractor tire. Try and position the tank above the valve stem so that gravity will assist in the liquid transfer.

With the anti-freeze now in the tractor tire again remove the valve core from the valve stem. Screw the special valve stem fitting onto the valve stem and a water hose onto the other side of the fitting. Rotate the tire so that the valve stem is at the top or 12 o'clock position. You now are ready to begin filling the tire with water. It will take a little while to do this since the tire is large and the orifice through which the water is entering the tire, i.e. the valve stem, is relatively small.

Continue filling the tire with water until it reaches the level of the valve stem. You can test this periodically by turning off the water, removing the fitting from the valve stem and seeing in water continues to drain out of the stem. If it does then you have filled the tire to or above the level of the stem. If it does not continue to drain out then the water level has not reached the stem level and additional water is required. Test the level frequently to avoid filling the tire way too far. The unfilled space left is valuable for expansion and contraction.

Some adapters have a little pushable tab (button like) which will allow you to test the water level without removing the hose. If your adapter has one then just turn off the water pressure and push the tab to check for water drainage.

After the tire has been filled to stem level reinstall the valve core. Now, air up the tire to about two or three psi less than the recommendations on the tire. This will allow the tractor to "squat" a little and gain maximum traction when digging, pulling equipment or etc.

Follow the same procedure for the other rear tire to complete the job. You will now have additional traction and stability for the tractor.