Bulbs

Flower Basics

Flower Beds & Specialty Gardens

Flower Garden

Garden Furniture

Garden Gnomes

Garden Seeds

Garden Sheds

Garden Statues

Garden Tools & Supplies

Gardening Basics

Green & Organic

Groundcovers & Vines

Growing Annuals

Growing Basil

Growing Beans

Growing Berries

Growing Blueberries

Growing Cactus

Growing Corn

Growing Cotton

Growing Edibles

Growing Flowers

Growing Garlic

Growing Grapes

Growing Grass

Growing Herbs

Growing Jasmine

Growing Mint

Growing Mushrooms

Orchids

Growing Peanuts

Growing Perennials

Growing Plants

Growing Rosemary

Growing Roses

Growing Strawberries

Growing Sunflowers

Growing Thyme

Growing Tomatoes

Growing Tulips

Growing Vegetables

Herb Basics

Herb Garden

Indoor Growing

Landscaping Basics

Landscaping Patios

Landscaping Plants

Landscaping Shrubs

Landscaping Trees

Landscaping Walks & Pathways

Lawn Basics

Lawn Maintenance

Lawn Mowers

Lawn Ornaments

Lawn Planting

Lawn Tools

Outdoor Growing

Overall Landscape Planning

Pests, Weeds & Problems

Plant Basics

Rock Garden

Rose Garden

Shrubs

Soil

Specialty Gardens

Trees

Vegetable Garden

Yard Maintenance

How to Test a Condenser in a Small Engine

How to Test a Condenser in a Small Engine. A condenser is part of the ignition system used on most small engines. The condenser is physically the same as a high voltage capacitor used in other types of electrical circuits. The small engine condenser stores a high voltage charge. A set of contacts are used to release that charge to the spark plug....

A condenser is part of the ignition system used on most small engines. The condenser is physically the same as a high voltage capacitor used in other types of electrical circuits. The small engine condenser stores a high voltage charge. A set of contacts are used to release that charge to the spark plug. If the condenser malfunctions, the small engine will not run. Various small engines have different locations for the condenser. Use the engine's specifications to remove the condenser from your particular make and model.

Things You'll Need

Needle type (analog) volt ohmmeter

Step 1

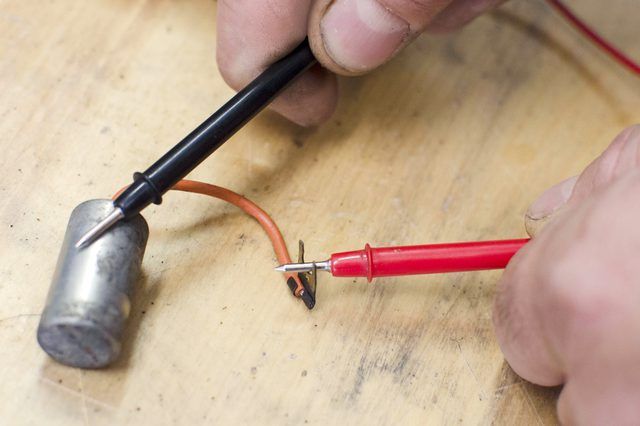

Remove the condenser from the engine. Place the condenser on an insulated wooden surface such as a workbench. A metal surface may cause the test to fail. You will note that there is a small metal connector located at the top of the condenser. This connector is the "hot" or power connection. The metal case of the condenser is the ground point.

Step 2

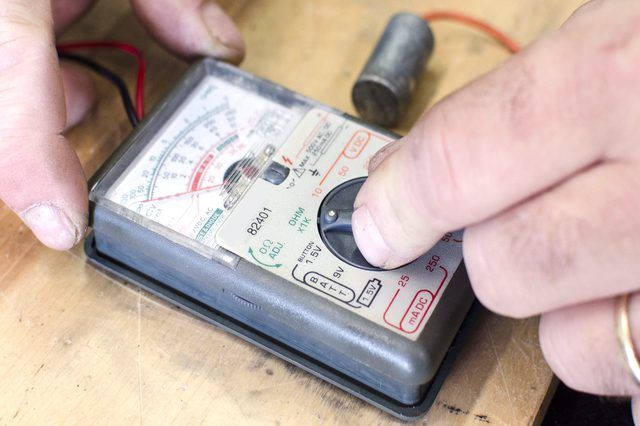

Switch the volt ohmmeter to the ohms position. Place the red lead into the "ohm" connector on the meter. Insert the black lead into the "com" or common connector on the meter.

Step 3

Touch the red lead to the hot connector on the condenser. Place the black lead to the metal case or ground point on the condenser. The meter's deflection needle should have jumped slightly to the right. The needle may also slowly rise in the right hand direction. Hold the leads in place for 15 seconds to 20 seconds. This action places charge to the condenser.

Step 4

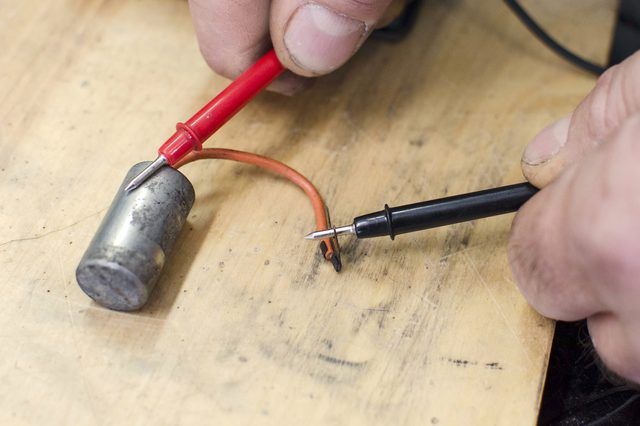

Remove the leads and reverse the placement to the condenser. In other words, move the red lead from the hot connector to the metal case, and move the black lead from the metal case to the hot connector. At the moment where both leads are touching the correct points, the meter should jump towards the right. This action discharges the condenser.

Step 5

Movement from the meter's needle indicates the condenser is good. If no movement was indicated on the meter in either circumstance in Step 3 or Step 4, the condenser is bad and must be replaced. Retest the condenser several times for a consistent reading.