Bulbs

Flower Basics

Flower Beds & Specialty Gardens

Flower Garden

Garden Furniture

Garden Gnomes

Garden Seeds

Garden Sheds

Garden Statues

Garden Tools & Supplies

Gardening Basics

Green & Organic

Groundcovers & Vines

Growing Annuals

Growing Basil

Growing Beans

Growing Berries

Growing Blueberries

Growing Cactus

Growing Corn

Growing Cotton

Growing Edibles

Growing Flowers

Growing Garlic

Growing Grapes

Growing Grass

Growing Herbs

Growing Jasmine

Growing Mint

Growing Mushrooms

Orchids

Growing Peanuts

Growing Perennials

Growing Plants

Growing Rosemary

Growing Roses

Growing Strawberries

Growing Sunflowers

Growing Thyme

Growing Tomatoes

Growing Tulips

Growing Vegetables

Herb Basics

Herb Garden

Indoor Growing

Landscaping Basics

Landscaping Patios

Landscaping Plants

Landscaping Shrubs

Landscaping Trees

Landscaping Walks & Pathways

Lawn Basics

Lawn Maintenance

Lawn Mowers

Lawn Ornaments

Lawn Planting

Lawn Tools

Outdoor Growing

Overall Landscape Planning

Pests, Weeds & Problems

Plant Basics

Rock Garden

Rose Garden

Shrubs

Soil

Specialty Gardens

Trees

Vegetable Garden

Yard Maintenance

How to Repair Low Voltage Landscape Lighting

How to Repair Low Voltage Landscape Lighting. If some of your outdoor low voltage landscape lighting is not working, the most likely cause is a bad connection. Landscape lighting wire is buried under the ground and has splices. The ground is a hostile environment that will corrode and damage wire splices, interrupting the electrical connection. The...

If some of your outdoor low voltage landscape lighting is not working, the most likely cause is a bad connection. Landscape lighting wire is buried under the ground and has splices. The ground is a hostile environment that will corrode and damage wire splices, interrupting the electrical connection. The majority of your repairs will involve the connections between the controller and the light. Manufacturers of outdoor lighting products realize the design weaknesses of their products and have come up with some innovative ideas to keep water out of the connection. One company not only uses waterproof wire-nut connectors, but also includes plastic bags to put over the splice to protect it. This method is highly recommended and is one of the best ways to keep water out of a splice.

Things You'll Need

Phillips screwdriver

Pliers

Connectors

Silicone

Plastic bags

Plastic ties

Step 1

If your low voltage landscape lighting does not turn on at the right time of day, check the controller for the correct time. Reprogram the controller to the correct time of day.

Step 2

If your low voltage landscape lighting is programmed correctly but still does not turn on, check that the controller has power and is plugged in.

Step 3

Check the light bulb to see if it is burned out. Replace the bulb if necessary.

Step 4

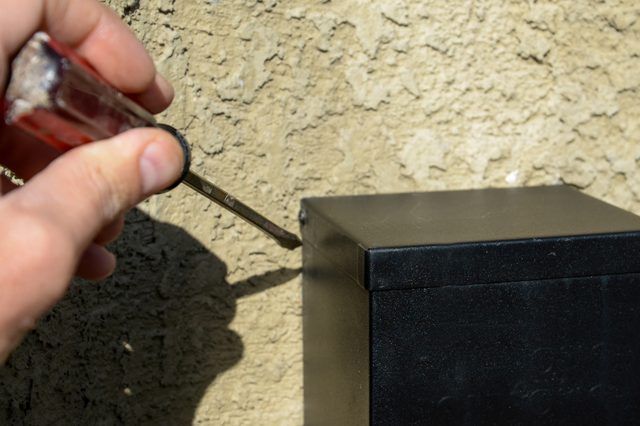

Remove the front panel of the controller to expose lighting wire connection. This is the wire that runs from the lights to the controller. Check the connection of the wire. Tighten if loose with a Phillips screwdriver.

Step 5

If the landscape light appears to be getting power from the controller but fails to turn on, dig up the splice. Make sure the connection is snug and tight.

Step 6

If the connection is loose, then disconnect the power source and unscrew the wire-nut connector.

Step 7

Look closely at the wires and the wire nut itself, checking for corrosion. Discard the wire nut and use a new one if there are signs of corrosion.

Step 8

Clean off both ends of the wire. Use pliers to splice wires together, twisting them together until snug.

Step 9

Twist on the wire-nut connector. Use a regular connector or a connector filled with silicone, or you can fill the connector with silicone yourself.