Bulbs

Flower Basics

Flower Beds & Specialty Gardens

Flower Garden

Garden Furniture

Garden Gnomes

Garden Seeds

Garden Sheds

Garden Statues

Garden Tools & Supplies

Gardening Basics

Green & Organic

Groundcovers & Vines

Growing Annuals

Growing Basil

Growing Beans

Growing Berries

Growing Blueberries

Growing Cactus

Growing Corn

Growing Cotton

Growing Edibles

Growing Flowers

Growing Garlic

Growing Grapes

Growing Grass

Growing Herbs

Growing Jasmine

Growing Mint

Growing Mushrooms

Orchids

Growing Peanuts

Growing Perennials

Growing Plants

Growing Rosemary

Growing Roses

Growing Strawberries

Growing Sunflowers

Growing Thyme

Growing Tomatoes

Growing Tulips

Growing Vegetables

Herb Basics

Herb Garden

Indoor Growing

Landscaping Basics

Landscaping Patios

Landscaping Plants

Landscaping Shrubs

Landscaping Trees

Landscaping Walks & Pathways

Lawn Basics

Lawn Maintenance

Lawn Mowers

Lawn Ornaments

Lawn Planting

Lawn Tools

Outdoor Growing

Overall Landscape Planning

Pests, Weeds & Problems

Plant Basics

Rock Garden

Rose Garden

Shrubs

Soil

Specialty Gardens

Trees

Vegetable Garden

Yard Maintenance

Poulan Chainsaw Repair

Poulan Chainsaw Repair. Poulan chainsaw repair involves troubleshooting techniques designed to isolate the cause of the failure. Following a 3-step systematic diagnostic routine can help minimize time and isolate the problem leading to quick and effective repair.

Poulan chainsaw repair involves troubleshooting techniques designed to isolate the cause of the failure. Following a 3-step systematic diagnostic routine can help minimize time and isolate the problem leading to quick and effective repair.

Things You'll Need

1 can of carburetor cleaner.

1 flat head screwdriver

1 replacement spark-plug

1 replacement air filter

1 replacement fuel filter

1 set of condenser and ignition points

Check Ignition System

Remove decking cover by removing three screws and unfastening the spark-plug boot. Remove the spark-plug.

Reattach spark-plug boot and hold spark-plug within 1/16-inch of clean metal surface on engine and pull starter rope. Observe for presence of strong spark between spark-plug and metal surface.

If spark is observed, the ignition is OK.

If no spark is observed, check the spark plug wire for cuts, breaks or loose connections which may lead to a short circuit.

Replace damaged wire.

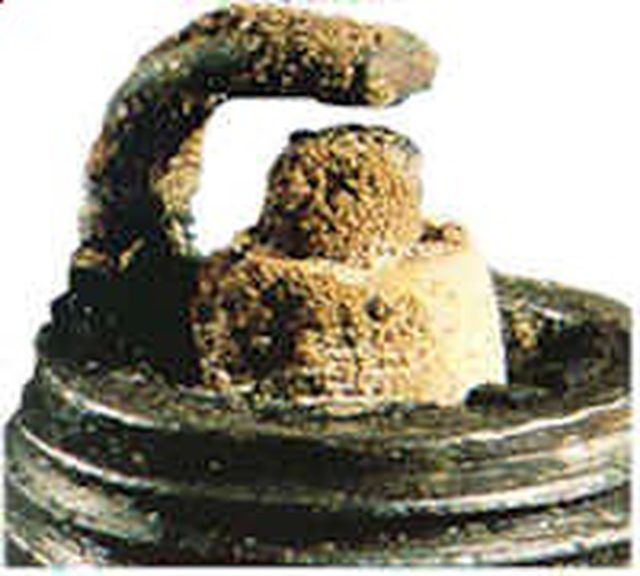

Check the appearance of the spark-plug electrode and sparking tip.

If the electrode and/or sparking tip are corroded with brown, black or reddish/rust-like deposits, replace the plug.

If the plug is wet and fouled with oil deposits, clean thoroughly with carburetor cleaner, dry and replace and look for source of oil fouling (below).

Replace the spark-plug if deposits are found or if the plug has been in heavy use for one year. Check and verify the spark-plug gap. If necessary re-gap the spark-plug to 0.025 inches ( 0.6mm).

Check the points and condenser (in an older model saw) and replace both if the points are burned or worn.

Check ignition module (in newer saws) and replace it if it is not producing a spark.

Check Fuel Supply and Carburetion

Ensure that the fuel (gasoline) supply is fresh and mixed in the proper mixture of gasoline and oil.

Poulan saws require a gas-oil mixture at a 40:1 ratio.

Inspect the spark-plug (step 5 above) to determine whether fuel is present on the plug.

A wet plug may indicate over choking, water in the fuel or an excessively rich gas-oil mixture.

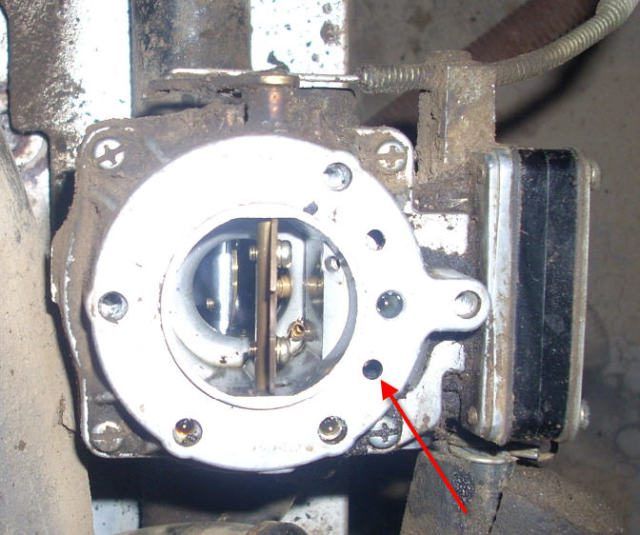

Check the choke valve function by removing the air filter and observing the choke valve to ensure that it opens and closes easily and closes completely in the carburetor throat.

Free sticking or rough operating choke valve by spraying choke shaft and into the carburetor venturi liberally with carburetor cleaner.

Attempt to start and run the engine with the fuel cap removed. If the engine runs, inspect the clean fuel vent to ensure air passages (small holes on top of gas cap) are clean and clear of blockage.

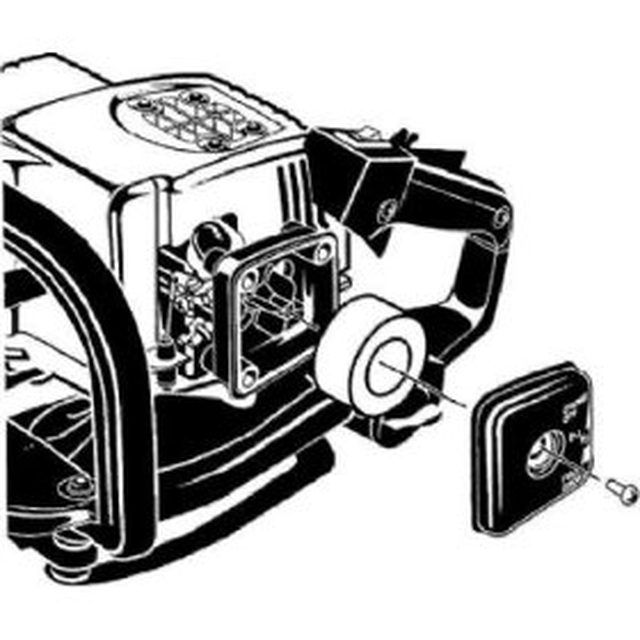

Inspect the air filter for contamination and/or blockage. Replace the dirty or discolored filter.

If a dry spark-plug is found in step 5 add fresh fuel mixture and crank engine. If the engine fails to start, remove the spark plug and pour 1 tsp. of gasoline into cylinder, replace plug and attempt to start engine.

If engines starts and runs for a few minutes and then dies check for blocked fuel supply.

Open the fuel supply line at the bottom of the tank, remove the fuel line and check for blockage by running a thin wire through the length of the line. Then replace the fuel line.

A dry plug indicates that fuel flow is blocked and may be the result of a dirty fuel filter, a stuck or a clogged inlet needle.

Check the fuel filter for blockage (dirty) by removing the (empty) gas tank and inspecting the filter cartridge. Discard and replace it if it is discolored or contamination is observed.

Replace the fuel filter annually to avoid problems.

Inspect the carburetor at high and low speed jets for varnish corrosion.

Clean by spraying with carburetor cleaner and use a thin, coated wire to plunge the opening.

Make Necessary Carburetor Adjustments

Allow the running engine to idle.

If the chain continues to rotate at idle, the idle speed is too high.

If the engine stalls at idle, the idle speed is to low.

Increase the engine speed by turning the idle screw clockwise.

Reduce idle speed by turning idle screw counter-clockwise.

Adjust idle speed until engine runs without chain moving or engine stalling.

Test engine speed by cutting through small section of wood.

If engine stalls readjust as in step 2 above.

Tips & Warnings

While air and fuel filters and spark-plugs may be cleaned instead of replaced it is a good idea to replace them after gaining access to most of these parts.

Keep ignition switch in "off" position when working with chainsaw adjustments.

Wear gloves when working with chain.