Bulbs

Flower Basics

Flower Beds & Specialty Gardens

Flower Garden

Garden Furniture

Garden Gnomes

Garden Seeds

Garden Sheds

Garden Statues

Garden Tools & Supplies

Gardening Basics

Green & Organic

Groundcovers & Vines

Growing Annuals

Growing Basil

Growing Beans

Growing Berries

Growing Blueberries

Growing Cactus

Growing Corn

Growing Cotton

Growing Edibles

Growing Flowers

Growing Garlic

Growing Grapes

Growing Grass

Growing Herbs

Growing Jasmine

Growing Mint

Growing Mushrooms

Orchids

Growing Peanuts

Growing Perennials

Growing Plants

Growing Rosemary

Growing Roses

Growing Strawberries

Growing Sunflowers

Growing Thyme

Growing Tomatoes

Growing Tulips

Growing Vegetables

Herb Basics

Herb Garden

Indoor Growing

Landscaping Basics

Landscaping Patios

Landscaping Plants

Landscaping Shrubs

Landscaping Trees

Landscaping Walks & Pathways

Lawn Basics

Lawn Maintenance

Lawn Mowers

Lawn Ornaments

Lawn Planting

Lawn Tools

Outdoor Growing

Overall Landscape Planning

Pests, Weeds & Problems

Plant Basics

Rock Garden

Rose Garden

Shrubs

Soil

Specialty Gardens

Trees

Vegetable Garden

Yard Maintenance

How to Cut & Polish Stones

How to Cut & Polish Stones. There is more than one use for a cut and polished stone. There is also more than one way to perform the task. Stones for jewelry are cut and polished using a much gentler process than stones for larger projects such as counter tops and building homes. Cutting and polishing stones of all kinds takes a similar process to...

There is more than one use for a cut and polished stone. There is also more than one way to perform the task. Stones for jewelry are cut and polished using a much gentler process than stones for larger projects such as counter tops and building homes. Cutting and polishing stones of all kinds takes a similar process to that of gemstones; the only difference is the size of the stone and the equipment needed to accommodate it.

Things You'll Need

Goggles

Face mask

Work gloves

Rock saw

Grinder

Sander

Fine and ultra-fine diamond grit paper

Lap belt

Manual Cutting and Polishing

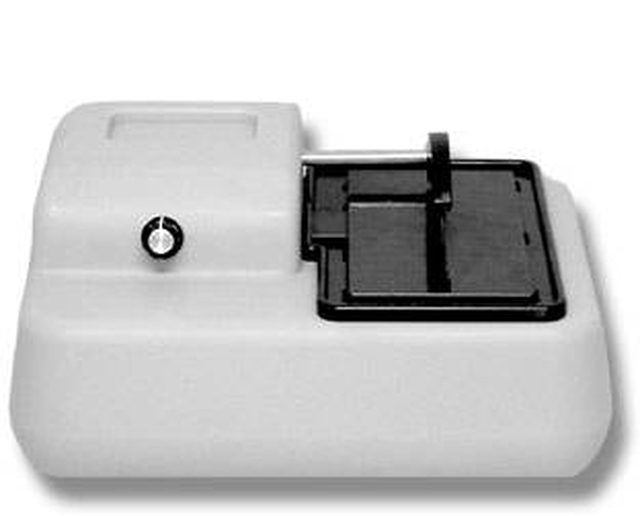

Don your goggles, work gloves and face mask. Cut the stone using a rock saw. Also called a slab, trim or Faceter's saw, it is made of circular blades ingrained with diamond grit. Steel, copper or phosphorus is used to make the saw. Choose the type of saw depending on the size of the stone and the desired finished product. Slab saws are up to 16 inches in diameter and the smallest, a Faceter's saw, is 4 inches in diameter.

Grind the rock to the desired rough shape using a grinder. A hand grinder is better-suited for larger pieces, while an all-in-one grinder/sander/polisher can eliminate some steps by utilizing the same machine. Grinding is done to shape the stones and to take off the rough edges.The grinding wheels use a slightly more fine diamond grit than in sanding. More inexpensive brands use silicon carbide wheels.

Sand the stones using sandpaper, fine diamond grit paper or a belt sander. Hand sanders are also appropriate. Sanding is used for finely shaping the stones and is the final step before polishing.

Polish the stone next by using a very fine diamond-ingrained grit. Polishing provides a mirror finish and performs the ultra-fine shaping needing for jewelry and display pieces.

Make a flat bottom on a piece to be used for jewelry by using a lap. It is a sander that sits flat. The stone is used against it to flatten out the bottom for a setting. You may have to revisit polishing, because the lap may create unwanted edges.